Hammer working weight

When purchasing a new hydraulic hammer, customers most often focus on the working weight of the hammer and excavator. There is some common belief that the hammer should have a working weight of 7-10% of the weight of the excavator on which it will be mounted. We really don’t know the roots of this data because no hammer manufacturer mentions it anywhere. Yes, indeed, in practice it somehow turns out to be 7-10%, however it is NOT a rule and it is NOT a professionally based data. Therefore, this principle should be adhered to exclusively INFORMATIVE and not taken as a strict rule, which many users do. This leads them to misconceptions that some traders skillfully turn to their advantage.

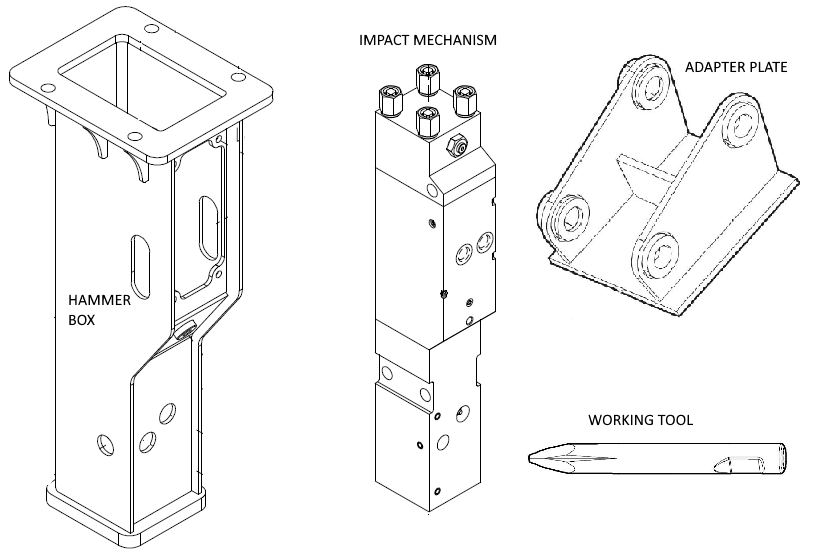

When we talk about hammer working weights, we need to clarify what a hammer working weight is. It represents the TOTAL weight with which the hammer loads the excavator (excavator boom), so it is the weight of the impact mechanism + hammer box (or hammer side plates) + adapter plate (connecting plate) + connecting hoses + working tool. This data is important for only one reason: in order to have data on how much weight the excavator boom will be loaded, ie the working weight of the hammer must be less than the maximum lifting capacity of the excavator boom (data most often associated with the maximum bucket capacity).

Example (simplified):

Total carrier weight: 20 tons

Carrier bool length (max): 8 m

Hammer working weight: 2500 kg

A hammer with a working weight of 2500 kg creates a moment (force × arm) on the maximally extended boom of the excavator: 2500 kg × 8 m = 20,000 kgm + weight of the boom itself with its torque.

Conclusion: this hammer would load a fully extended excavator arm with a “minimum of 20 tons” and the excavator would be at the limit of stability (overturning) and this hammer is NOT recommended for this type of excavator. A hammer of less working weight should be installed.

And this is where any further analysis of the working weight of the hammer ends. The working weight of the hammer does NOT provide information on the efficiency of the hammer, its impact force / energy. Why is that so? Simply because the hammer does NOT "hit" with the hammer box, the connecting plate, the connecting hoses or the tool (in terms of impact energy).

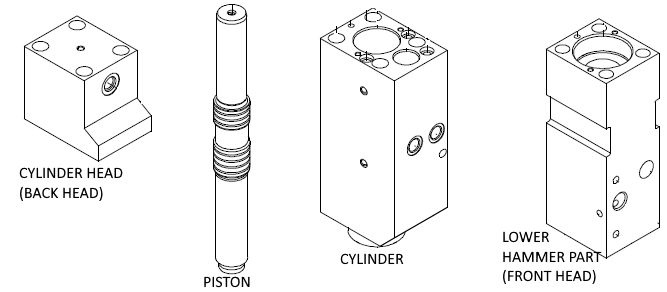

The impact energy of the hammer is produced in the so-called. IMPACT MECHANISM whose main parts are: PISTON, CYLINDER, CYLINDER HEAD, LOWER PART OF THE HAMMER.

The impact energy delivered by the hammer depends, among other things, on the size of the piston. To obtain higher impact energy, a larger impact piston is required, which entails a larger cylinder and a larger cylinder head and lower part of the hammer. So, for higher impact energy, we basically need a larger impact mechanism. It follows that a heavier impact energy requires a HEAVIER impact mechanism = a heavier hammer. But if we already want to compare hammers by weights then, as a compromise, we should only compare the weights of IMPACT MECHANISMS, which in practice (based on data available only from the brochures of hammer manufacturers) is almost impossible.

Working weight of the hammer in relation to the data from the plate on the hammer ("delivery weight")

Each new hammer comes with a plate with basic hammer information. The example below is a hammer with a working weight of 1200 kg. However, the plate states the delivered weight ("Deliv.wt") of 942 kg. Data that is quite eye-catching, especially for those users who do not understand what the working weight of the hammer is and what the delivered weight is.

The delivered weight represents: the weight of the impact mechanism + the weight of the box. Does not include the weight of the tool, adapter plate and connection hoses. In essence, as various models of tools can be mounted on the hammer, but also various versions of adapter plates, we conclude that the data on the working weight is, in fact, only an approximate data that can not even be known before mounting the hammer on the excavator. Another fact that supports the thesis that the working weight of the hammer is LESS IMPORTANT data!

Example of manipulation of hammer working weight data

Hammer model | Working weight, kg | Working press, bar | Oil flow, l/min | For carriers tons | Market price, € |

A (side plates type) | 305 | 100-160 | 35-60 | 3,5-6 | 5.200 |

A (box type) | 400 | 100-160 | 35-60 | 3,5-6 | 5.500 |

B | 200 | 100-150 | 35-65 | 2,5-6 | 5.500 |

The data in the table are copied from the official catalogs of manufacturers A and manufacturers B. The listed prices are approximate. Model A belongs to the lower class of hammers, model B belongs to the higher class of hammers.

Comparing the same manufacturer A that offers the performance of the same hammer in sides plates and in the box, we notice that the difference in the working weight of the hammer (between two completely IDENTICAL percussion mechanisms) is as much as 95 kg, or about 30%. This difference is made by a piece of steel that encloses the percussion mechanism and has NOTHING to do with the efficiency of the hammer. The choice of model A in the box is justified only because it is a silenced model, with less vibration. The delivered impact energy is the SAME, although many customers will look for the Model A in the box just because it is heavier.

Furthermore, if we look at model B which has “only” 200 kg, this model, according to the data on oil flow and working pressure, works with the same parameters as model A, and is lighter by 200 kg or 50%.

At first glance, if the customer compares only the working weights of the hammer, he can very easily be misled and buy a model A that has the same price as the model B, but is twice as heavy! However, according to the operating parameters (oil flow and operating pressure) it is offered two identical hammers. For the Model A the customer pays only very expensive iron and double the weight means nothing but that it will unnecessarily load the excavator boom, make it harder to handle the hammer, increase the consumption of the wear parts of the excavator boom and increase fuel consumption.

As we know from experience that lower class hammers are less sophisticated and most often represent mediocre copies of top brands, these hammers have a very low efficiancy. Therefore, the same operating parameters (due to large losses) do not mean the same delivered impact energy. In the example above, the Model B has even higher impact energy than the Model A although it is twice as light. This means that the Model B is even cheaper if we buy impact energy (€ / Joule) and not the weight of "poor" iron (€ / kg)