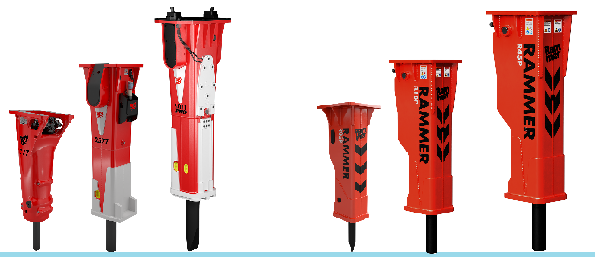

RAMMER hydraulic hammers

GENUINE.

EXCELLENCE RANGE PERFORMANCE RANGE

RAMMER impact technology KRUPP impact technology

When it comes to hydraulic hammer technologies, RAMMER technology is one of the most commonly copied technologies. This means that RAMMER is the one that, for the past 35 years, has been setting standards in the field of hydraulic hammer technology. Certainly, one of the world's leading manufacturers of hydraulic hammers, RAMMER is a name that is unreservedly mentioned among the TOP 3 world manufacturers.

- - faster response to customer requests (direct contact with the factory via WT GRUPA)

- - direct after-sales support (service and spare parts WT GRUPA)

- - very reasonable hammer price/quality ratio (direct line from the factory, without expensive intermediaries)

- - reasonable prices of original spare parts

Origin: | Finland |

Basic technical features: | Working principle is oil (Excellence line) and oil/gas (Performance line). The small hammer Excellence lines are solid body construction (no tie rods), while all other models are tie rods design. The hammers are made with a membrane, except for small Performance lines. They are of exceptional material quality, durable and reliable. |

Target market segment: | The target group of users are companies with large operational requirements, large projects and very frequent use of hammers (Excellence lines). For the same market segment, but with slightly smaller requirements, Performance line models are better solution. |

Investment and maintenance costs: | The initial investment is slightly higher. With a service contract, unplanned costs are kept to a minimum. Regular maintenance is in the middle cost range with very small downtime. Preventive maintenance further reduces the risk of higher and unexpected costs. |

Expected lifetime: | With regular maintenance, the objectively expected service life is very long, 7000-10,000 working hours, which in some cases can mean up to 20 years of real operation. |

Residual value: | The expected residual value after the expected lifetime is 40% -50% of the value of the new hammer with a high probability of placing on the market. Possible trade in deal with old hammers. |